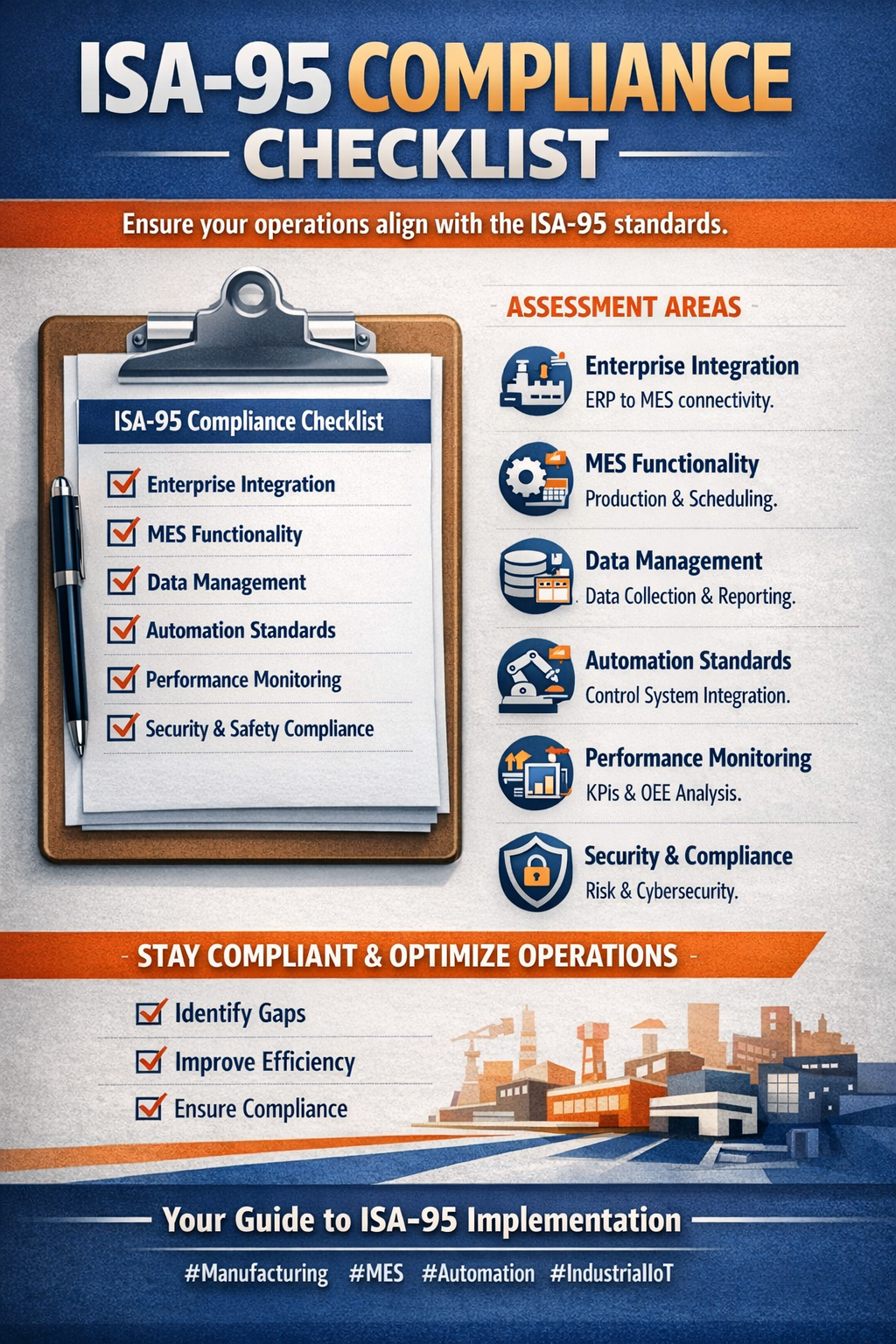

ISA-95 Compliance Checklist (Manufacturing Industry)

$0.00

Description

This ISA-95 Compliance Checklist provides a comprehensive, step-by-step approach for manufacturing organizations to evaluate their current systems against ISA-95 requirements. It covers enterprise planning, manufacturing operations management, data standardization, system interoperability, cybersecurity, and performance management.

The checklist helps organizations:

-

Reduce system integration complexity

-

Improve production visibility and traceability

-

Enable standardized data exchange across IT and OT layers

-

Support regulatory compliance and audit readiness

-

Accelerate MES, ERP, and Industry 4.0 initiatives

Designed for system integrators, manufacturing engineers, IT/OT teams, and digital transformation leaders, this checklist serves as both an assessment tool and an implementation roadmap.

1. Enterprise–Control System Integration (ISA-95 Levels)

☐ Clear separation and definition of ISA-95 Levels 0–4

☐ Documented data flow between ERP (Level 4) and MES (Level 3)

☐ Defined interfaces between MES and SCADA/PLC (Levels 2–1)

☐ No direct ERP-to-control-system communication

2. Business Planning & Logistics (Level 4)

☐ ERP system manages orders, inventory, and supply chain

☐ Production schedules are generated at enterprise level

☐ Standardized master data (materials, BOMs, routings)

☐ Change management procedures for business rules

3. Manufacturing Operations Management (Level 3 – MES)

☐ MES implemented for production, quality, maintenance, and inventory

☐ Work instructions digitally managed and version-controlled

☐ Production execution tracked in real time

☐ Labor, equipment, and material usage captured

☐ Electronic batch/lot records (if applicable)

4. Quality Operations Management

☐ Quality checks integrated into MES workflows

☐ Non-conformance and deviation tracking

☐ SPC (Statistical Process Control) data collection

☐ Traceability from raw material to finished product

☐ Audit-ready electronic records

5. Maintenance Operations Management

☐ Preventive and predictive maintenance workflows defined

☐ Equipment health and downtime tracked

☐ Maintenance data integrated with production schedules

☐ Asset lifecycle data standardized

6. Inventory & Material Management

☐ Real-time inventory visibility at shop-floor level

☐ Material consumption recorded against production orders

☐ Lot/batch traceability maintained

☐ Inventory reconciliation between MES and ERP

7. Data Modeling & Standardization

☐ ISA-95 object models adopted (Equipment, Material, Personnel)

☐ Standard naming conventions for assets and processes

☐ Consistent data definitions across systems

☐ Master data governance established

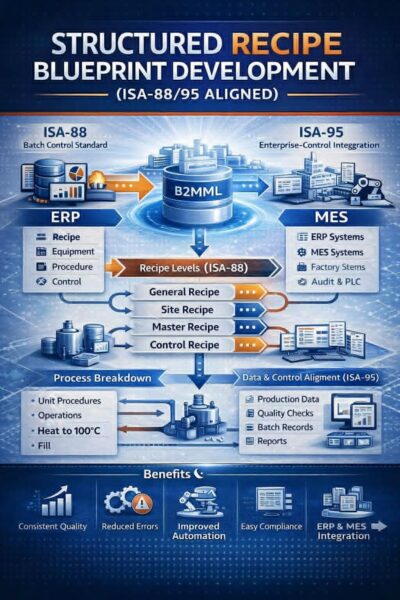

8. Information Exchange & Interoperability

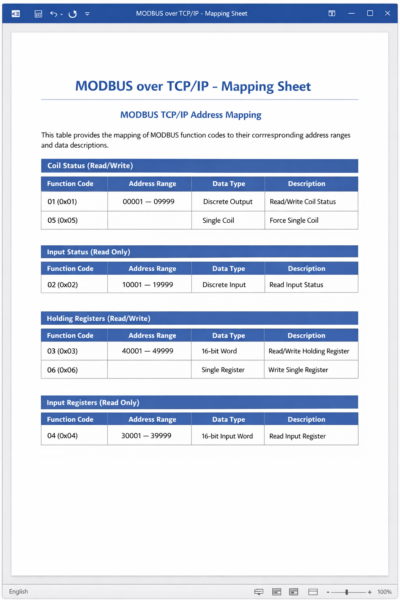

☐ Standard interfaces (API, OPC UA, B2MML) implemented

☐ Message structures aligned with ISA-95/B2MML schemas

☐ Error handling and data validation mechanisms

☐ System interoperability tested and documented

9. Cybersecurity & Access Control

☐ Role-based access control across all ISA-95 levels

☐ Secure communication between enterprise and control layers

☐ Audit trails enabled for critical operations

☐ Compliance with ISA/IEC 62443 (where applicable)

10. Performance Management & Reporting

☐ KPIs aligned with ISA-95 (OEE, yield, throughput)

☐ Real-time dashboards for production visibility

☐ Automated reporting to ERP and management systems

☐ Continuous improvement processes supported

11. Documentation & Governance

☐ System architecture diagrams aligned with ISA-95

☐ SOPs for system integration and data management

☐ Compliance audits scheduled and documented

☐ Training programs for operators and engineers