Welcome to IACS Engineering — your 24/7 global partner for OT–IT integration, Industry 4.0 enablement, multi-vendor communication protocol profiling, advanced process control (APC) engineering, reusable controller library development, and process control expertise in batch, continuous or discrete control.

With more than 20 years of consultancy and engineering experience, our team of highly qualified professionals (PhD, MEng, BEng) — including Principal Control Systems Engineers, Senior Control Systems Engineers, and Senior Process Control Engineers — has delivered solutions across diverse sectors such as food & beverage, pharmaceuticals, manufacturing, material handling, robotic warehouses, energy storage systems (ESS), mining, and water & wastewater treatment.

At IACS Engineering, we bring together deep expertise in both Operational Technology (OT) and Information Technology (IT) to provide specialized engineering services that accelerate your Industry 4.0 transformation and drive reliable, scalable, and intelligent automation.

IACS Engineering – Design & Development Capability Matrix

Engineering Designs & Development Capabilities

- System Architecture & OT/IT Network Topology Design

- Control Loop Architecture: ON/ OFF, PID Control, Pressureless Conveyor Control (PCC), Leader–Follower Control

- Advanced Process Control: Cascade PID Control, Split-Range PID Control, Ratio Control, and MPC (Model Predictive Control)

- Functional Design Specifications (FDS): Control Philosophy, Alarm Philosophy, States, Fail-safe Logic, Interlocks, Permissives

- Process Control Object Libraries & Digital Twin Simulation Objects

- Inspection & Test Plans (ITP), FAT/SAT development with PFDs, P&IDs, Electrical Schematics, IO Lists

- API Development for Automation & IIoT

- R&D Case Studies in Process Modeling, Control & Communications

- Energy Optimization & Control Cost Studies

- Circular Economy Integration for Recycled Material Streams

Process Control Objects Library Development

- Object-oriented IEC 61131-3 structured, reusable, & maintainable libraries

- Multi-vendor Experience

Digital Twin / Simulation Library Development

- Simulation frameworks for testing control libraries

- Portable FAT/SAT testing simulators

- IO simulation, sequences, interlocks & alarms

- Auto-filled FAT/SAT reports with timestamps

Process Optimization

- Optimal process parameter calculation

- Multivariate regression analysis & data modeling

Communication Protocols

- Ethernet/IP (CIP), PROFINET, Modbus TCP, OPC UA, MQTT, EGD, AS-i, SNMP, IEC 61850

- DeviceNet, Profibus DP, CANbus, Modbus RTU, DNP3

Industrial IoT Experience

- Azure IoT Hub & Azure IoT Edge

- Custom APIs (Modbus TCP, OPC UA, MQTT)

International Standards Experience

- ISA-88 Batch Process Control

- ISA-106 Procedure Automation

- ISA-95 Enterprise Integration

- IEC 61131-3 Object-Oriented PLC Programming

- ISA-18 Alarm Management

- ISA-5 / ISA-20 Instrumentation Documentation

- ISA-84 / IEC 61511 Functional Safety

Why Choose Us for Industrial Automation & Control Systems Engineering Services and Consultancy

Expertise That Delivers Results

With over 20 years of experience in industrial automation, process control, control systems engineering, and R&D in advanced control theory, we provide high-performance engineering solutions that improve reliability, efficiency, and operational excellence.

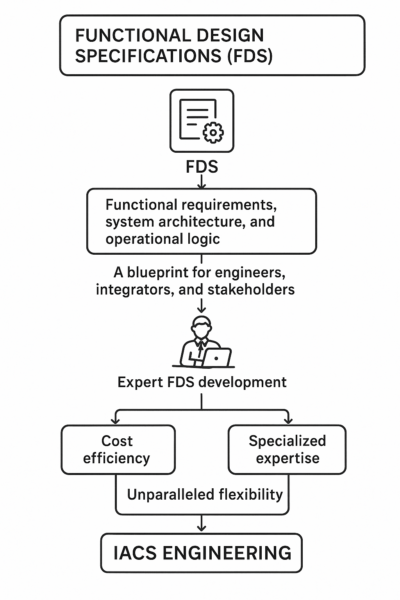

Complete Functional Design Specification (FDS) Development

- Functional decomposition & hierarchical control layers

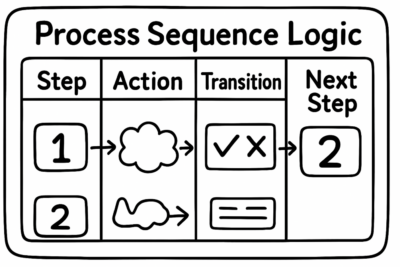

- System states, modes, and operational transitions

- Software architecture & structured programming

- Control philosophy development

- Permissives, interlocks & fail-safe logic

- Alarm management philosophy

- Communication protocol profiling

- Automation layers integration (ERP, MES, SCADA)

- Sequence modeling & state-based control design

- Collaborative robotic process automation (RPA)

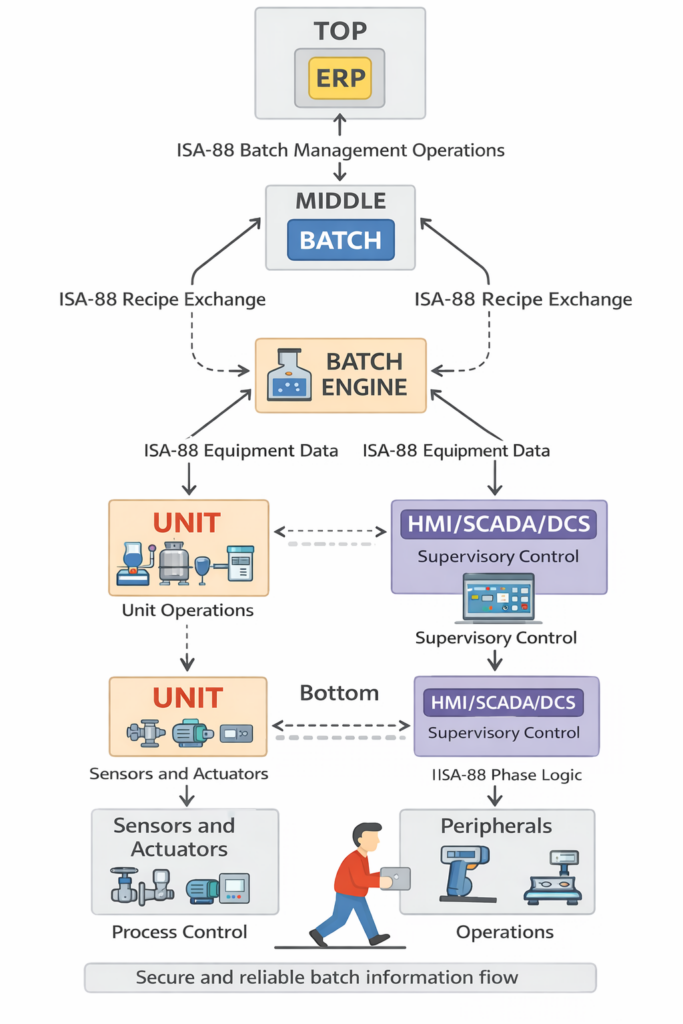

ISA-88 Implementation Expertise (Batch Control & Recipe Management)

- Batch manufacturing control based on ISA-88 (IEC 61512) standards

- Physical, procedural, and process model definition (units, equipment modules, control modules)

- Standardized batch recipe structures: general, site, master, and control recipes

- Separation of recipes from equipment for flexibility and reuse

- Batch control strategies for sequential, continuous, and hybrid processes

- Phase logic design, state models, and exception handling

- Equipment capability modeling and batch allocation strategies

- Recipe versioning, approval workflows, and change management

- Batch execution, scheduling, and coordination with ISA-95 Level 3 systems

- Integration of batch systems with MES, historians, and ERP platforms

- Material tracking, genealogy, and batch traceability

- Management of batch records, electronic batch records (EBR), and audit trails

- Compliance support for regulated industries (e.g., GMP, FDA 21 CFR Part 11)

- Alarm, event, and exception handling in batch operations

- Secure and reliable batch information exchange across control and enterprise layers

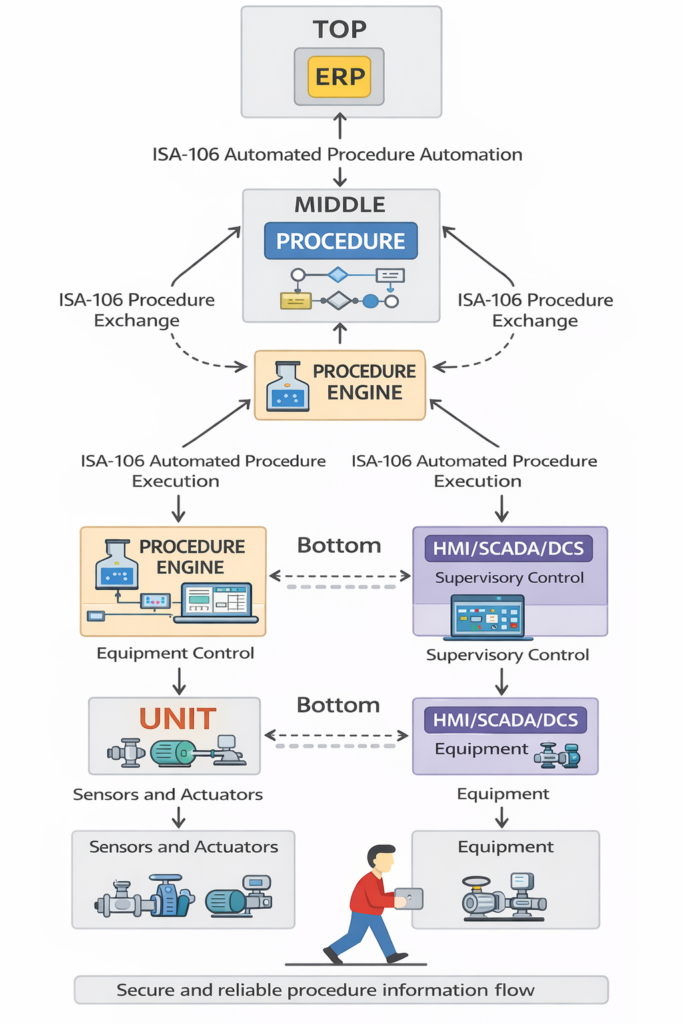

ISA-106 Implementation Expertise (Procedural Automation for Continuous & Hybrid Operations)

- Procedural automation based on ISA-106 (IEC 63280) recommended practices

- Standardized procedural models for continuous and hybrid manufacturing processes

- Definition of procedures, operations, phases, and steps independent of equipment control

- Clear separation of procedural logic from basic control strategies

- State-based procedural execution with well-defined transitions and hold/restart behavior

- Operator-centric procedural guidance and workflow enforcement

- Consistent execution of operating procedures across units, lines, and sites

- Design of reusable procedural templates and libraries

- Management of normal, abnormal, and emergency procedural paths

- Integration of ISA-106 procedures with DCS, PLC, and SCADA systems

- Coordination of ISA-106 procedural control with ISA-88 batch logic in hybrid plants

- Alignment of procedural automation with ISA-95 Level 3 manufacturing operations

- Procedure versioning, change management, and approval workflows

- Support for alarm handling, deviations, and exception management

- Improved safety, operability, training, and operational consistency

- Secure and reliable procedural information flow across enterprise and control layers

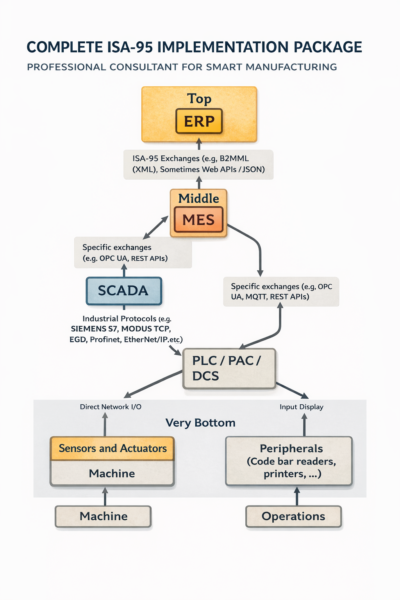

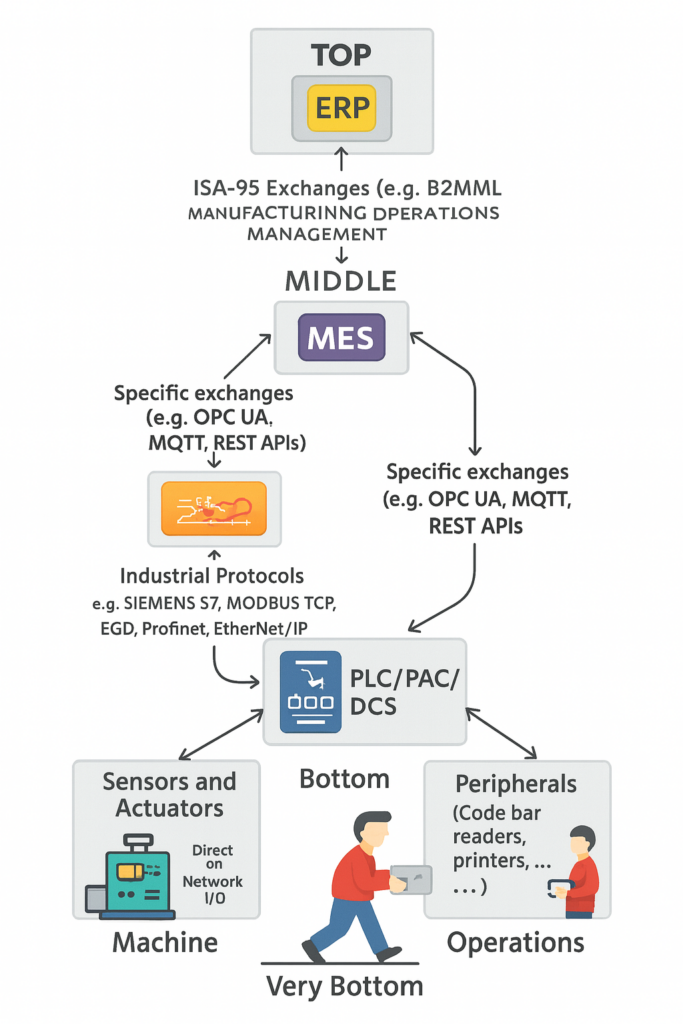

ISA-95 Implementation Expertise (Enterprise-Control System Integration)

- Manufacturing Operations Management (MOM) & Layered ISA-95 architecture

- Level 3–Level 2 integration frameworks for MES–SCADA

- ISA-95 structured data models for assets, materials, and operations

- Standardized tag naming, equipment models & terminology harmonization

- Production workflow, scheduling & resource modeling

- Information exchange models for KPIs, OEE, downtime & traceability

- Designing interfaces between ERP (SAP, Oracle, Microsoft) and MES/SCADA

- Implementing Level 3 functions: production, quality, maintenance & inventory operations

- Secure, reliable industrial information flow across enterprise systems

Transparent & Predictable Pricing Schedule

- Principal Consultancy: *from USD 149/hour (plus GST/VAT)

- Senior Control Systems / Senior Process Control Engineers: *from USD 89/hour (plus GST/VAT), minimum 4 billable hours

- Flexible Engagement Models: fixed-price, retainer-based, or project-based agreements

- Micro-consulting: Productized services available

You always know exactly what you’re paying for—no surprises, no hidden costs.

Project-Based & On-Demand Freelancer Engagement

For well-defined automation and control engineering projects, we provide project-based and on-demand freelance support through vetted subcontractors and specialist engineers. This model ensures flexible and cost-effective execution, without the need for long-term commitments.

Vendor Agnostic, Independent Consulting

We deliver unbiased, vendor-agnostic consulting focused entirely on the solutions that best fit your operational, technical, and industry requirements. Our recommendations are not influenced by any specific OEM or technology provider.

Training, Upskilling & Knowledge Transfer Sessions

We provide custom one-to-one training, team upskilling, and knowledge transfer programs tailored to your automation systems, process control needs, and digital transformation roadmap. These sessions strengthen long-term capability within your engineering and operations teams.

Get 24/ 7 Expert Support

Contact us today for a consultation and discover how we can optimize your automation and control systems.

OT & IT Vendors We Experienced:

VSD/ VFD Vendors We Experienced:

Communication Protocols We Experienced:

Gateway Vendors We Experienced:

Databases, APIs, VMs, Portals We Experienced:

Book our obligation-free consultation session today

Place the below-mentioned free consultation order with all your details and we shall contact you back:

-

FDS Development Consultancy – Obligation Free 15 mins Session

$0.00 Add to cart -

Industrial Automation and Control Systems (IACS) Engineering – Free 15 Mins Consultation

$0.00 Add to cart -

Modular, Scalable & Maintainable Siemens PLC Library Development (TIA Portal) – Obligation Free 15 mins Session

$0.00 Add to cart

Book our paid micro-consultancy and engineering services today

In our productized services model, you pay for outcomes and expertise — not billable hours or inflated staffing. Each engagement is delivered directly by a principal or senior, self-managed consultants and engineers, with no middle layers, no body-shopping, and no hidden overheads.

This means you can confidently engage our services without funding unnecessary engineering managers, program managers, or project managers — only the people actually creating value work on your problem.