We view and apply ISA-88 , also known as ANSI/ISA-88 or IEC 61512, as a control system engineering standard primarily focused on the structured integration of physical and procedural models for batch processing systems. It defines a hierarchical physical model that categorizes equipment into Process Cells, Units (where primary processing occurs), Equipment Modules (which perform specific control-oriented functions like heating or cleaning), and Control Modules (which are field-level devices such as valves, motors, and sensors). ISA-88 also defines a procedural control model that separates recipe logic from equipment control, enabling flexible and modular automation.

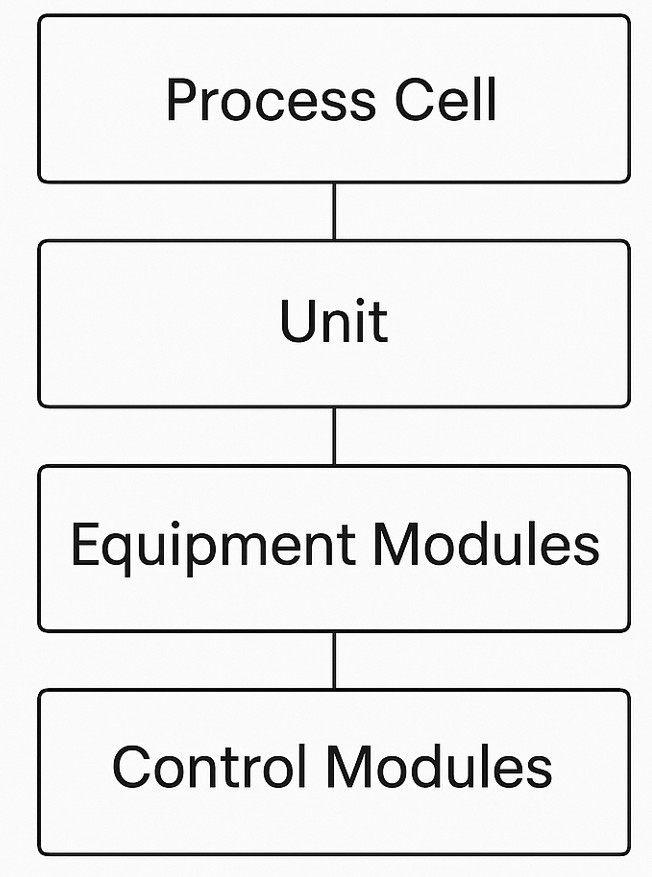

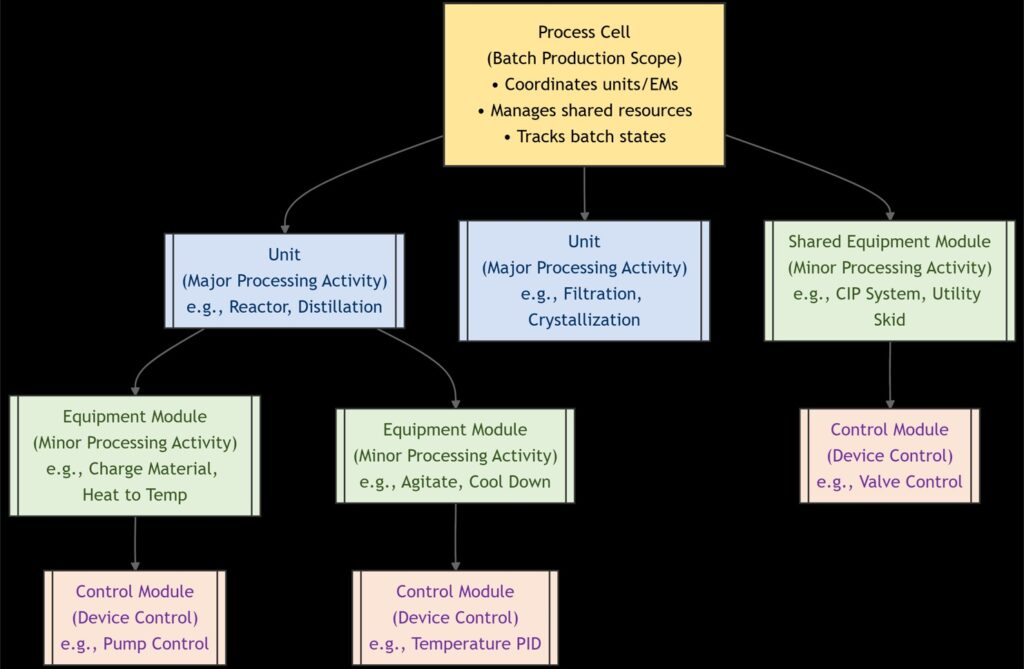

Key Physical Model Hierarchy

- Enterprise → Site → Area → Process Cell (serves as an organizational and coordination boundary)

- Unit – where major processing takes place. So, Units = Major process steps (batch ownership).

- Equipment Module (EM) – performs minor activities, often involving sequences or sub-processes, e.g. it executes a phase (say, “Heat to 170°C”) by orchestrating CMs (PID loop, heater controls). So, heats material to a setpoint” → Minor processing activity. So, EMs = Minor/auxiliary tasks (phase execution).

- Control Module (CM) – individual field-level devices or basic control elements like valves, motors, sensors, etc. So, CMs = Device-Level Control

| Layer | Functional Purpose | Owns Procedural Logic? |

| Process Cell | Coordinates resources (Units, EMs) to produce one or more batches. Manages workflows, shared equipment, and scheduling. | ❌ No |

| Unit | Performs a major processing activity (e.g., reaction) on one batch. | ✅ Yes (Operations) |

| Equipment Module (EM) | Performs a minor processing activity (e.g., heating) via phases. | ✅ Yes (Phases) |

| Control Module (CM) | Controls devices (e.g., valves, PID loops). | ❌ No (Basic control only) |

💡 Benefits of Implementing ISA-88

ISA-88 (Batch Control) is indeed a control system engineering standard designed to address modularity, reuse, and consistency in batch processing industries like pharma, food & beverage, and chemicals.

- Modular Design: Enhance flexibility and scalability by structuring your control systems into modular components.

- Improved Consistency: Standardize batch processes across different equipment and facilities.

- Enhanced Integration: Facilitate seamless communication between control systems and enterprise-level applications like MES and ERP.

- Regulatory Compliance: Simplify adherence to industry regulations by maintaining consistent and well-documented processes.

⚠️Common Misconceptions

⚠️ Common Misconception

❌ “Process Cell performs the highest-level processing activity.”

✅ Reality: Units/EMs perform processing; the Process Cell is the arena where processing happens.

Hierarchy Visualization

How to Define a Process Cell (Criteria)

- Production Scope:

- “Does this grouping produce complete batches?” (e.g., a vaccine, a chemical intermediate).

- Resource Pool:

- “Which Units and shared EMs are exclusively dedicated to these batches?”

- Coordination Needs:

- “Is centralized scheduling/resource arbitration required?”

Example:

- Process Cell:“Penicillin Fermentation Cell”

- Units: Fermenter-101, Fermenter-102

- Shared EMs: Media Transfer System, CIP Skid

- Not: “Heating Process Cell” (heating is a minor activity → EM).

Key Takeaway

- Units/EMs/CMs are functional (defined by processing task).

- Process Cell is organizational (defined by batch production scope).

🛠️ Our ISA-88 Implementation Services

Our team of experienced Principal Control Systems Engineer (PhD, MEng, BEng in Electrical, Mechatronics and Control Systems Engineering with 18 plus years industry experience) and Senior Process Engineer (MEng, BEng in Chemical and Petroleum Engineering with 15 plus years industry experience) work together and offers comprehensive ISA-88 implementation services tailored to your specific needs:

- Assessment & Planning: Evaluate your current systems and develop a strategic plan for ISA-88 integration.

- Design & Development: Create detailed designs for equipment and procedural models in line with ISA-88 standards.

- System Integration: Implement and integrate ISA-88 compliant systems with your existing infrastructure.

- Training & Support: Provide training for your staff and ongoing support to ensure successful adoption and operation.

📈 Industries We Serve

Our ISA-88 implementation services are applicable across various industries, including:

- Pharmaceuticals

- Food & Beverage

- Chemicals

- Biotechnology

- Consumer Goods, etc.

📞 Get Started Today

Ready to enhance your batch processing capabilities with ISA-88 standards? Contact us today to schedule a consultation and discover how our expert services can benefit your operations.